产品咨询

产品咨询

售后咨询

售后咨询

客户留言

客户留言

2025-12-08

On December 3, 2025, FLANGCO welcomed members of the Lean Management Study Group from the Yixing Green Low-Carbon Industry Association to its headquarters for a visit. As a benchmark company in lean management within the industry, FLANGCO's continuous improvement in lean management provides ongoing momentum for enhancing operational efficiency and strengthening differentiated competitiveness, while also attracting the attention of the Yixing Green Low-Carbon Industry Association.

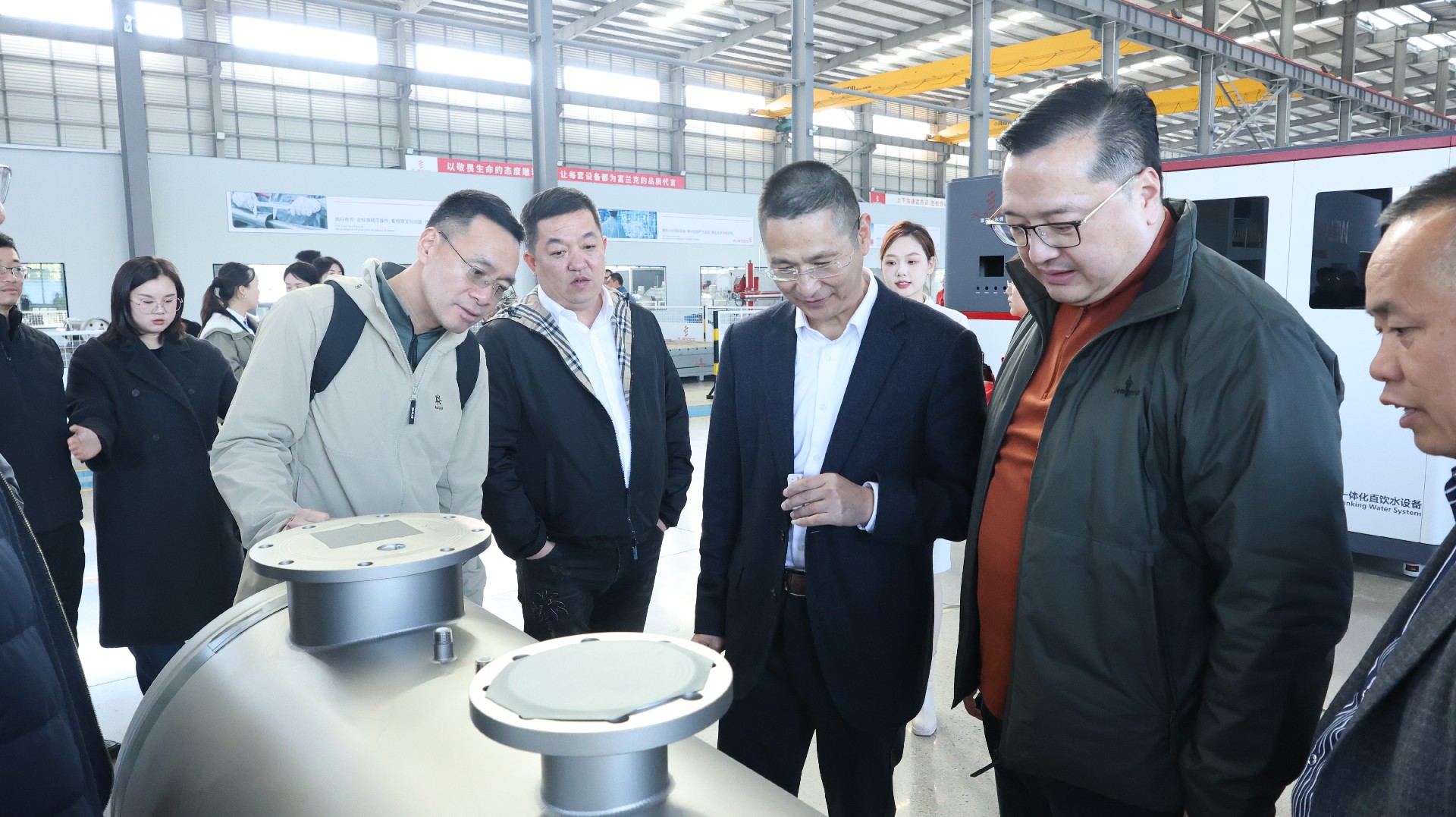

Corporate Exhibition Hall: Integration of Technology and Management

On the afternoon of the 3rd, the study group first visited the FLANGCO exhibition hall, which showcased the full range of FLANGCO’s products, from smart water system solutions and municipal water supply and drainage equipment to intelligent operation and maintenance platforms, demonstrating FLANGCO’s one-stop digital comprehensive service capabilities in "full-process consulting, R&D design, manufacturing, and maintenance services."

Through professional explanations, the study group observed the results Frank has achieved in standardized and regulated management. Additionally, FLANGCO's lean management model offered the group a replicable and promotable demonstration paradigm.

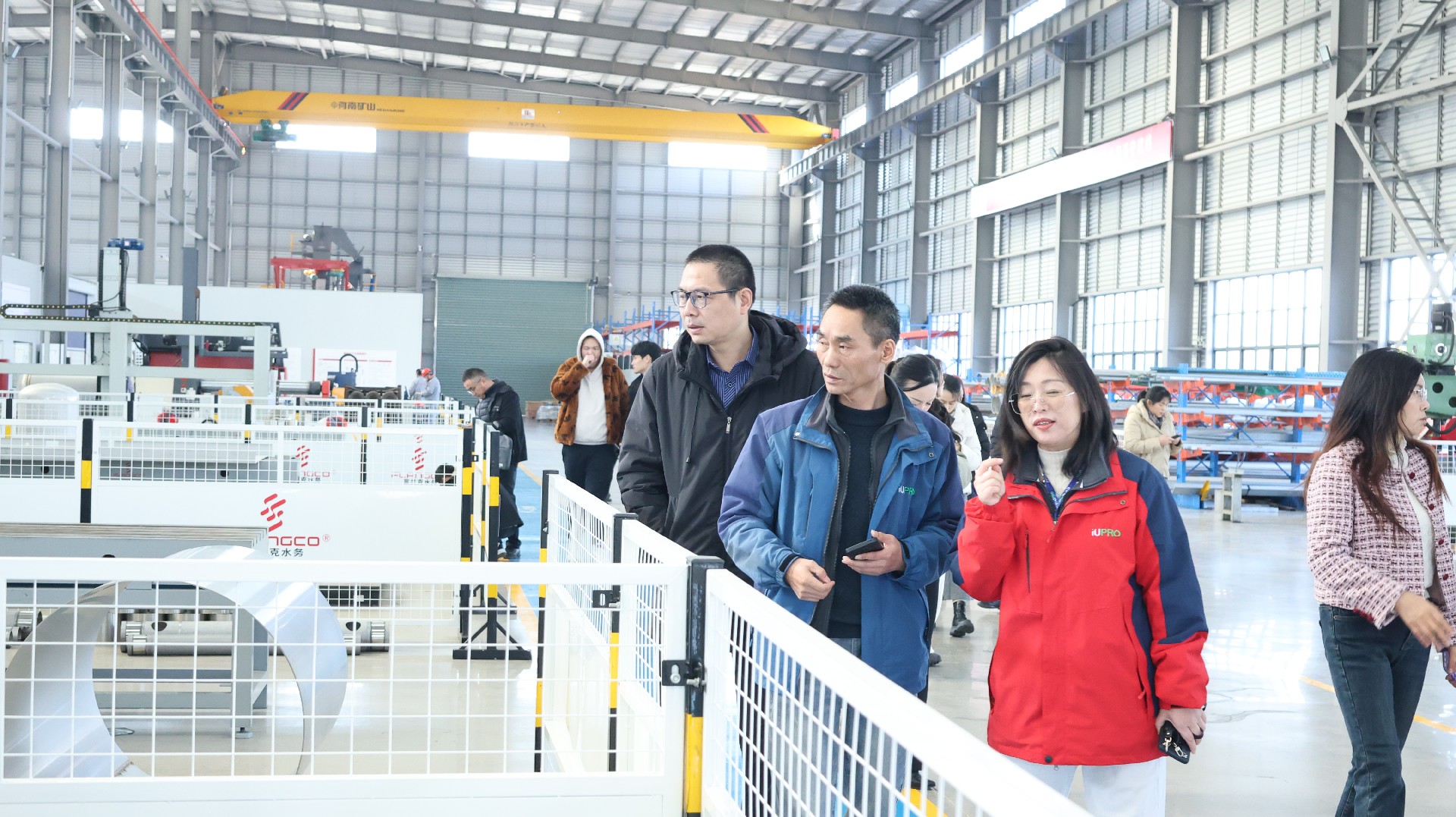

Production Workshop: Excellence in Details

Next, the study group toured FLANGCO's production workshop to learn about the company’s practices in site management, area identification, visual management, and standard operations. From tool placement in the sheet metal processing area to standardized procedures in the assembly and commissioning area, the 8S management philosophy is thoroughly implemented in FLANGCO’s production workshops.

1. Site Management

Material placement follows the "three-fixed principle," ensuring “everything has its place, and everyone has their responsibility,” which improves employee work efficiency.

2. Area Identification

Different functional areas and equipment in the workshop are clearly labeled and divided to ensure production safety and optimize management.

3. Visual Management

Electronic boards in the workshop display real-time, accurate production data, creating an efficient, fully visible management process.

4. Standard Operations

Fixed and repeatable procedures and methods are established to achieve high-efficiency, safe, and high-quality production in the workshop.

Dual-Carbon Strategy: Cultivating New Productivity Together

This benchmark study activity allowed the lean management study group to understand the important role of FLANGCO’s lean management in driving sustainable company growth. Members expressed that they would integrate lean management concepts into their own corporate innovation practices to promote sustainable development.

Under the guidance of the dual-carbon strategy, FLANGCO will continue to explore and progress in the green and low-carbon transformation, learning from peers, and working together to ensure the high-quality development of the water supply industry!

2026-02-02

2025-12-08

2025-11-19

2025-11-17

2025-11-04

2025-10-29

2025-10-27

2025-10-16